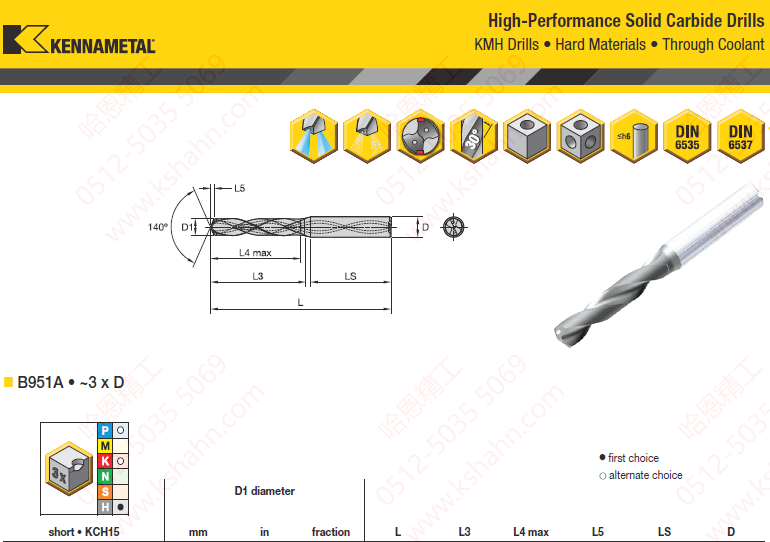

New KMH Drills for Hard Materials

The all-new KMH solid carbide drills are engineered for hard material applications up to 65 HRC. The B94_drill

series without through coolant is specifi cally designed to machine hardened and surface-hardened materials

using fl ood coolant. With its 145° point angle, it is also perfectly suited as a pilot drill for the B95_drill series

with through coolant and 140° point for deeper applications.

Both series come with an increased core to strengthen the drill, feature a curved cutting edge with corner

chamfer to avoid chipping on the margin lands and increased tool life in these challenging materials.

New KMH Point Design

• Curved cutting edge with corner chamfer for maximum corner stability in hard materials.

• Avoids chipping on cutting edge and pre-mature wear.

• Also works well in applications with heavily-interrupted cuts using the make-to-order four-margin version.

Special Flute Design

• Strong web to increase the strength of the drill in tough applications with short chips.

• B94_ series with 15° helix angle to maximise stability in applications above 54 HRC.

• B95_ series with 30° helix angle to improve chip evacuation in higher length-to-diameter ratios.

New KCH10 and KCH15 Grades

• KCH10 on B94_ series consists of a special fi ne-grain carbide substrate with higher hardness.

• KCH15 on B95_ series, with its higher toughness, supports edge strength at increased rake angles, which are applied to improve chip evacuation in higher L/D ratios.

• Both series carry a high temperature and shock resistance AlTiN coating for machining hardened materials to increase tool life.