TAPER PIPE THREAD GAGES

N.P.T. (National Taper Pipe)

To gage Internal N.P.T. taper pipe threads, screw the N.P.T. thread plug firmly into the product – do not force.

The thread is within the permissible tolerance when the gaging notch of the plug is not more than one turn plus or minus

from being flush with the end of the product. N.P.T. plugs are regularly furnished with the basic step only. Minimum and

maximum steps can be added on request. To gage External N.P.T. taper pipe threads, screw the N.P.T. thread ring on

to the product as far as it will go without using force. If the face of the small end of the ring is flush with the face of the

product the thread is basic. The permissible tolerance is one turn plus or minus from basic.

A.N.P.T. (Aeronautical National Pipe Taper)

A.N.P.T. internal taper pipe threads are basically the same as the N.P.T. pipe threads except that for Army and

Navy Aeronautical use they must be more carefully controlled for diameter, taper and thread form.

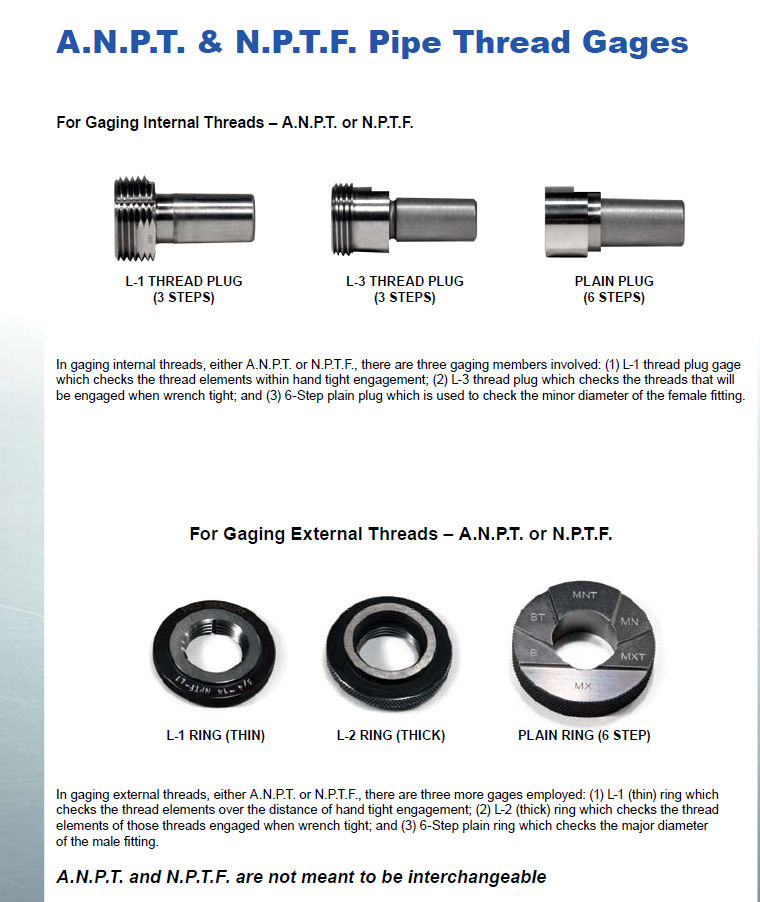

To gage Internal A.N.P.T. taper pipe threads, check first with the A.N.P.T. L-1 thread plug gage. This plug

differs in dimensions from the N.P.T. plug and has minimum and maximum steps in addition to the basic step. If the

face of the product is between the minimum and maximum steps of the plug, the product is in tolerance. The A.N.P.T.

L-3 plug gage is used to check the three threads beyond the L-1 depth. As a check on taper the “reading” on the L-3

thread plug must be within one-half turn of the “reading” on the L-1 thread plug gage. The truncation is checked with

a six-step plain taper plug gage. This plug has minimum and maximum truncation steps for each of the three pitch

diameter conditions – Minimum, Maximum and Basic. If the L-1 plug shows the product to be basic pitch diameter,

the face of the product should lie between the basic minimum and the basic maximum steps of the truncation plug. If

the pitch diameter is minimum, the part should fall between the MN and MNT step. If the pitch diameters maximum,

the part should fall between the MX and MXT steps. No appreciable shake or wobble is permitted. Shaky fit indicates

taper error.

To gage External A.N.P.T. taper pipe threads, first check with the A.N.P.T. L-1 ring. The small end of the

ring must be within one turn plus or minus of being flush with the end of the product thread. Note exactly what this

“standoff” is and compare it with the “standoff” obtained with the A.N.P.T. L-2 thread ring. As a check on taper the total

tolerance on standoff variation between the L-1 and L-2 rings must not exceed one-half turn. The truncation is checked

with a six-step plain taper ring gage. This ring has minimum and maximum truncation steps for each of the three pitch

diameter conditions – Minimum, Basic, and Maximum. If the L-1 ring shows the part to be basic pitch diameter, the end

of the part should fall between the B and BT steps on the six-step plain ring. If the pitch diameter is minimum, the part

should fall between the MN and MNT step. If the pitch diameter is maximum, the part should fall between the MX and

MXT steps. No appreciable shake or wobble should be permitted. Lead, angles and root truncation should be checked

whenever possible, by projection as a check on tool wear.

See Military Standard AS71051 latest edition for complete specifications

N.P.T.F. (National Pipe Taper Dryseal Pressure-Tight Joints)

N.P.T.F. Internal taper pipe threads may be gaged in the same manner as the A.N.P.T. threads. Gages are

dimensionally different, however, and must not be interchanged. The turns method may be substituted for the “standoff”

method to compensate for gage and product chamfers. With the turns method, the number of turns are counted from

hand tight engagement to complete release, and the gaging steps are completely disregarded. A tolerance of plus

or minus one turn is permitted from the basic number of turns specified. As a check on taper, the difference in turns

between the L-1 and L-3 plugs shall be within one-half turn of the difference between the basic turns engagement of the

plug gages. Truncation must be within the proper limits on a six-step dryseal plain taper plug gage.

N.P.T.F. External taper pipe threads are checked in the same manner as A.N.P.T. threads. Gages are

dimensionally different, however, and must not be interchanged. The turns method may be substituted for the “standoff”

method to compensate for gage and product chamfers. A tolerance of plus or minus one turn is permitted from the

basic number of turns specified. As a check on taper, the difference in turns engagement with the L-1 and L-2 dryseal

rings shall be within one-half turn of the difference between the basic turns engagement of the ring gages.